Keg Washers and Fillers

Bring your craft beer project to life with ease and peace of mind using our Keg Washers and Fillers. The cleanliness of a keg is an essential element of maintaining your brand and reputation and the contents of the keg will leave a lasting impression on consumers. Equally as important is the ability to fill the kegs in a timely and efficient manner to prevent wasting money down the drain in the form of beer.

Your Bespoke Solution

Our keg washers have evolved over the years to include the steps to ensure your product is entering an environment to keep it so fresh, and so clean. Whether you have your own fleet or use a keg rental service, our keg washers allow you to customize the washing cycle to fit your needs. We are bespoke by name and nature, so we offer customization if your situation requires it.

Sterilization is a critical component in keg washers. We have been working on incorporating steam and acid sterilization in our keg washers, as we understand not all breweries will have steam on site.

Additionally, our units help drive consistency and efficiency in your keg cleaning and filling processes. The units are equipped with industry-leading components, including a magnetic flowmeter to ensure every fill is consistent and on point. The unit will provide you with the information you need to understand your filling process so you can troubleshoot any issues that might arise.

We offer manual counter-pressure keg filling options ranging from single-keg filling apparatus to multi-keg filling manifold. The counter-pressure filling system allows you to purge your kegs with CO2, remove oxygen, and fill the keg with beer without foaming issues in minutes.

All of our manual keg filling equipment comes complete with a Micromatic coupler type of your choice and banded beer hose, so you’re ready to start kegging as soon as you receive your filler.

If you have a preferred design to our BBS standard or want us to design something bespoke for you, contact us and we’d be happy to provide a quote.

Lastly, if you experience any issues with your unit, don’t worry, as all units are equipped with a remote module that allows us to log in and monitor, update the programming logic, and adjust the HMI to meet your specific needs.

Configurations

- Single, Dual, and Triple washing head options are available

- Multiple spear-engaging orientations based on preference

- All keg spear types accepted

- Up to 3 tanks

- Up to 3 pumps

- Steam or electric heating options

- All Keg Washers are CE certified. UL componentry upgrade available

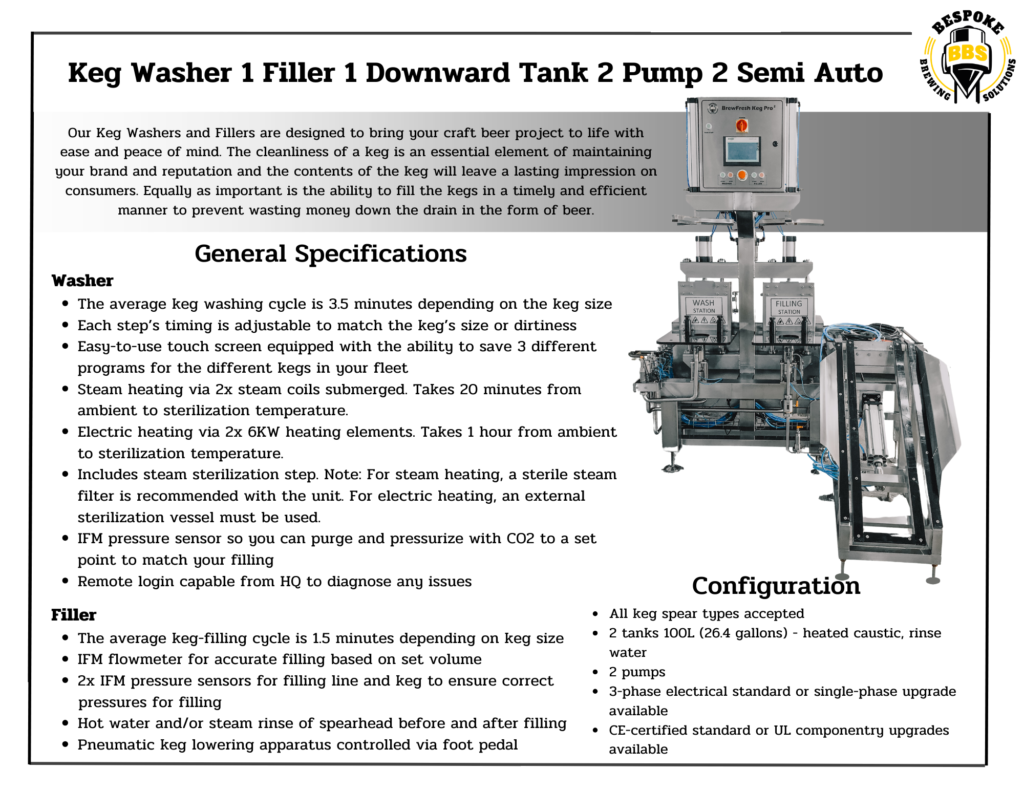

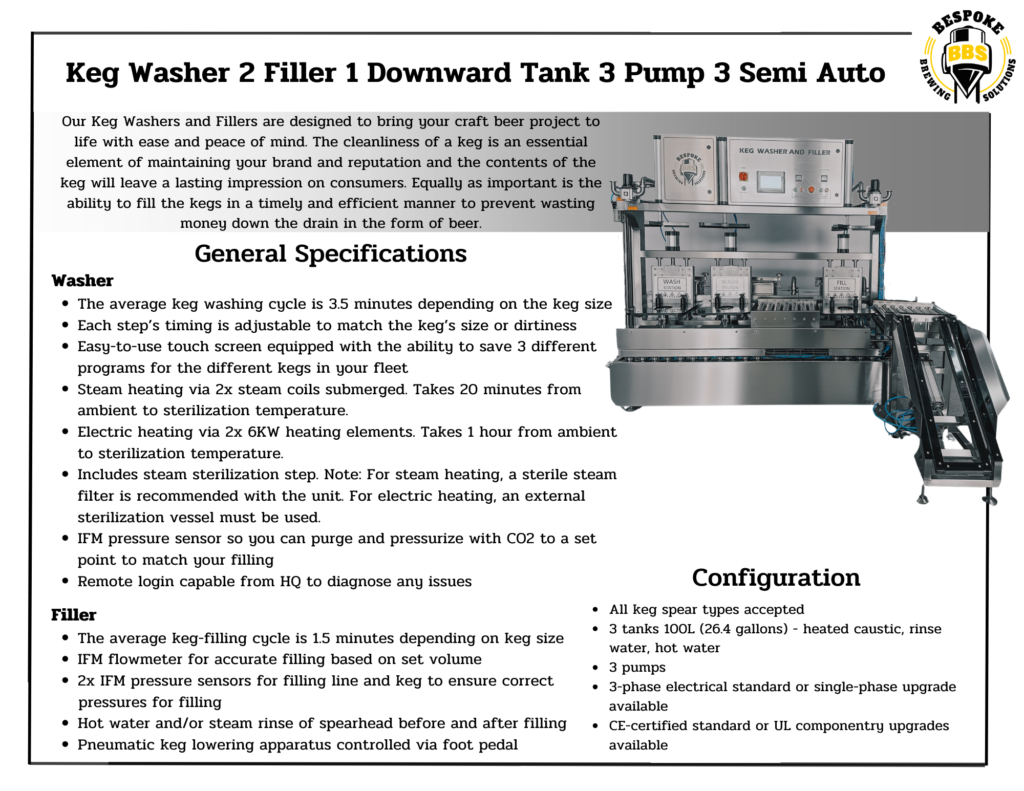

General Specifications

Washer

- The average keg washing cycle is 3.5 minutes depending on the keg size

- Each step’s timing is adjustable to match the keg’s size or dirtiness

- Easy-to-use touch screen equipped with the ability to save 3 different programs for the different kegs in your fleet

- Steam heating via 2x steam coils submerged. Takes 20 minutes from ambient to sterilization temperature.

- Electric heating via 2x 6KW heating elements. Takes 1 hour from ambient to sterilization temperature.

- Includes steam sterilization step. Note: For steam heating, a sterile steam filter is recommended with the unit. For electric heating, an external sterilization vessel must be used.

- IFM pressure sensor so you can purge and pressurize with CO2 to a set point to match your filling

- Remote login capable from HQ to diagnose any issues

Filler

- The average keg-filling cycle is 1.5 minutes depending on the keg size

- IFM flowmeter for accurate filling based on set volume

- 2x IFM pressure sensors to ensure correct pressures for filling

- Hot water and/or steam rinse of spearhead before and after filling

- Pneumatic keg lowering apparatus controlled via foot pedal

Our Keg Washer Offerings

‘Bespoke saw our potential – and we saw so much potential in them as a partner going forward. We had several other quotes from other companies, all of whom had strong names in the industry, with more experience. We went with Bespoke because of the trust factor. There was much less bureaucracy of people to deal with and other projects that took precedence. It was a very personal relationship, and John was just as invested in the outcome as we were. He said ‘we want to make it the best it can be, just like you do’ and he really meant it, you could see he was incredibly genuine.’

Shaya Rubinstein, Head Brewer at Urban Alley

Brewery Projects Highlight

Tell us about your craft beer project

If you’ve never started a brewery before, we’re here to help. If you’re an experienced brewer, we speak your language.

Whatever your craft beer project, we can bring it to life.