Here at Bespoke Brewing Solutions, we like to share things.

We share our lunches in the office. We share tips about the best place to buy sushi.

And you may have noticed, we like to share our knowledge.

We hope you enjoyed our previous blogs in this series – the first was on your brewery layout and the second on the design of your brewhouse.

Well – now it’s time for utilities!

Once the equipment layout and the design have been locked in, we can start working on the different utilities which will be whipping around the brewery.

This includes:

- Electrical

- Steam

- Liquor

- Glycol

- Gas (Compressed Air, Oxygen, CO2)

In this article – which is Part One of our utilities blog – we will be looking at what to consider for all your brewery electrical requirements.

Volts and Hertz

When we start a project one of the first emails we send out is to confirm the following:

Single-Phase Electrical Voltage:

Three-Phase Electrical Voltage:

Hertz:

This is absolutely critical. We order all of our equipment (motors, pumps, etc) and design our control panels, to work with the required voltage(s) and hertz. (Note that these differ around the world.)

For instance, we have produced three-phased equipment to work on 208V and 480V at 60Hz for the US and 415V at 50Hz for the UK and Australia.

If this information is not communicated correctly, you could end up with unusable equipment. Which, as we can all imagine, is a very costly mistake.

Pro Tip: When looking for possible brewery sites, make sure to ask if there is three-phase electrical power running into the building. This is because pumps and motors work better running on three-phased electrical – especially as they increase in power.

Once this is determined you should confirm the electrical current for each system. This is a critical gate check for location consideration.

Brewery Electrical Layout

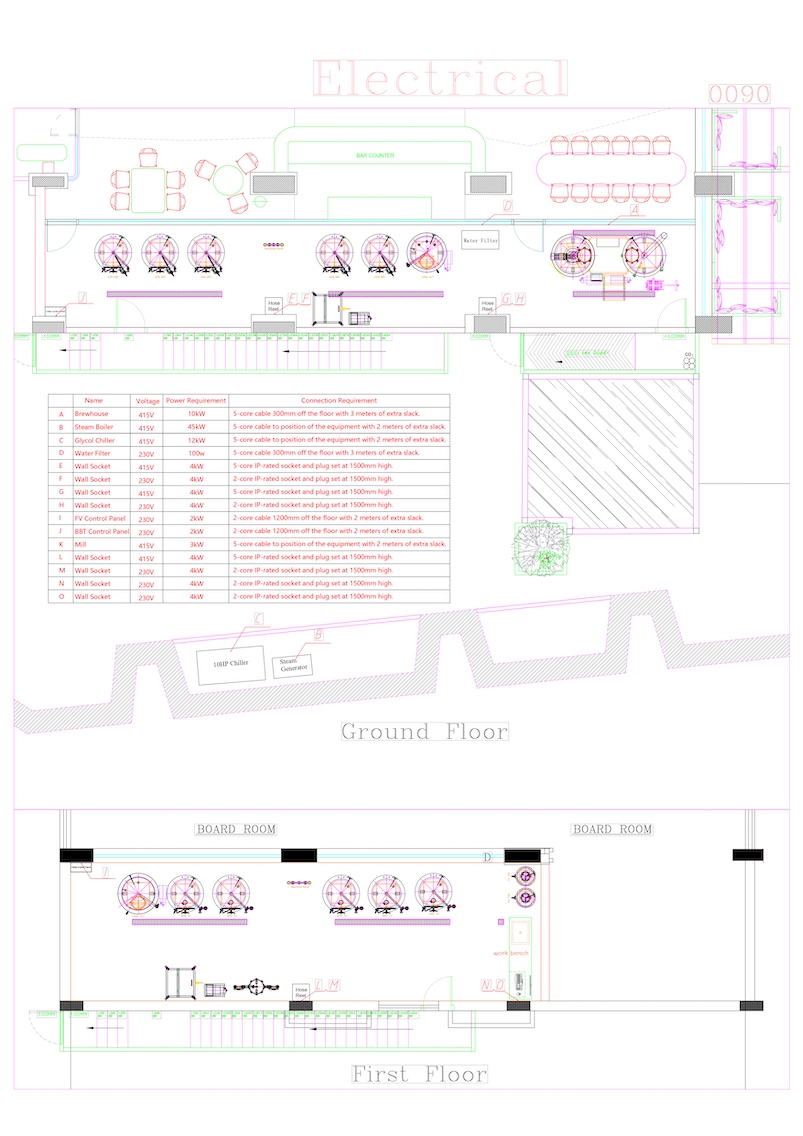

In our electrical layout drawing (provided for all projects) we list all the equipment which will be drawing power – and the wattage required.

From there, the local electrician(s) can help confirm if you have enough juice (current) coming into the building to meet the demand.

If not, you might need to run more power to the location which can be costly. If you have equipment coming from other manufacturers, we are more than happy to incorporate them into our drawings.

For every brewery project we have done thus far, we have directly worked with the electrician(s) to include as much detail as possible in the drawing to indicate placement, connection type and any special requirements.

We want to make sure they are comfortable with the equipment. Electrical wire coloring differs around the world!

Brewery Electrical Design Drawings

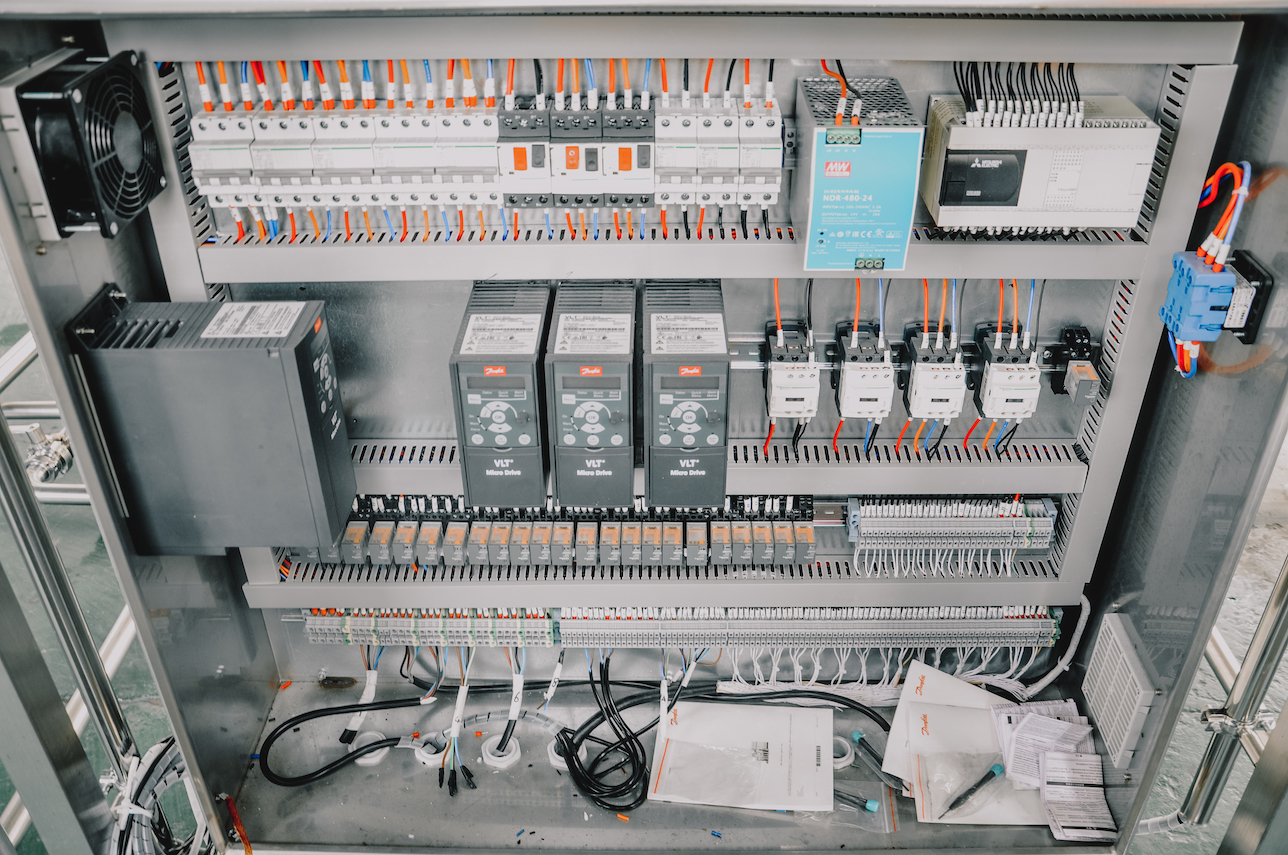

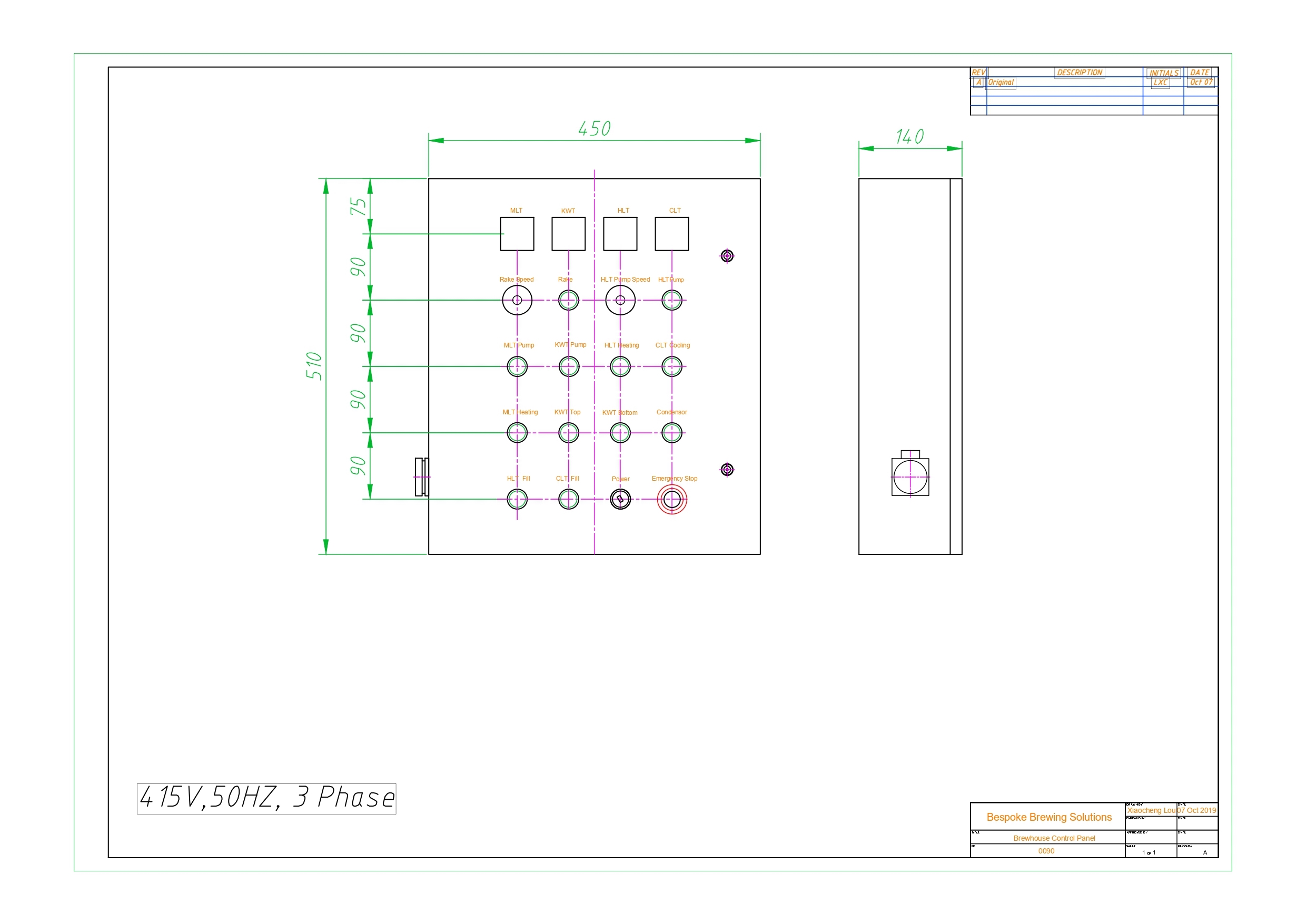

We also provide design drawings for control and electrical cabinets for brewhouses, mobile pumps, CIP carts, etc.

This includes the button configuration – with labeling for control cabinets and more importantly electrical wiring diagrams for the cabinets.

This prevents confusion on what will be controlled from where – and the naming as local nomenclatures differ around the world for brewing equipment.

The electrical diagrams will help the local team to plan out not only their route for the power cables around the brewery, but also need to consider electrical wiring for the different components around the brewery (such as pumps, motors, solenoids, sensors, etc.)

As an example – the brewery’s electrical cabinet will need to be wired to all components of the brewhouse. If this includes the HLT and it is located on the other side of the brewery, then cables will need to be run for the pump, solenoid(s) and thermocouples.

A Bespoke Solution

There is a lot to think about with respect to the electrical requirements of your brewery.

This is because you also need to consider both power and controls – which all should be identified ahead of time.

We are always learning – and we’d be lying if we said we have not had any issues! But we are continuously improving after each project.

We know the dos and don’ts! Let us bring this experience into your project, to help it go smoothly.

Get in touch with us for more information.