The definition of bespoke is “made for a particular customer or user.”

At Bespoke Brewing Solutions, we don’t believe in the ‘one size fits all’ approach. Our team can provide a service to meet your needs — whatever they may be.

With us, you’re not just getting commercial brewing equipment, you’re entering a partnership with a team of brewing experts.

We are brewing equipment designers, consultants, manufacturers, and installers. We’re ready to turn our experience into your brewing business.

Here is how we do things — the Bespoke way:

1. Understanding Your Brewery Needs

What we do:

We start our process with an email exchange, conversation or video call about your brewery needs — whether you know exactly what you want or are looking for some guidance.

Below are the topics that we like to cover in order to determine what equipment will help bring your craft beer project to life:

- Monthly and annual production goals

- The different brands or types of beers planned

- Location sizing (if already identified)

- Budget

- Heating method

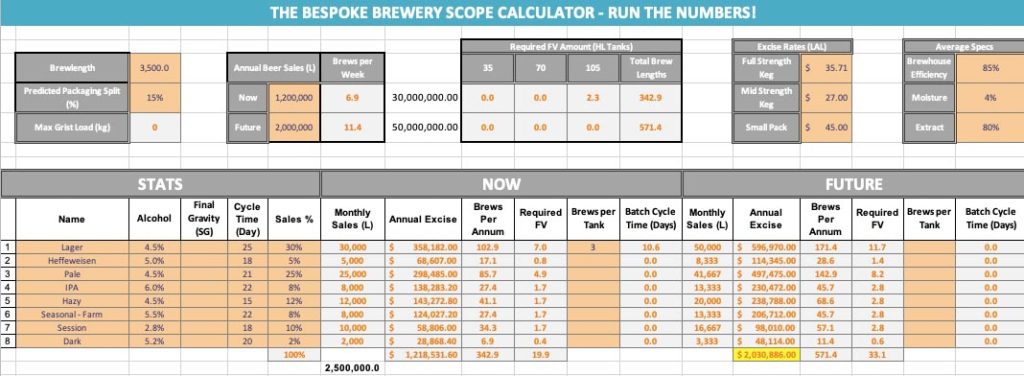

Via our in-house brewery scope calculator (shown below), our team will put together a quote we feel is best for your needs based on the information you provide.

If pricing looks good and within budget, at this stage, we work towards a freight quote via our preferred freight forwarder to give you an all-in delivered cost to your door.

From there, we can set up a time to review the quote in detail and how Bespoke can help make it a reality.

During this meeting, we not only want to guarantee that the equipment is in line with what you need, but we also like to see if there is any room for savings or a staged approach.

Why we do it:

At BBS, we like to share our knowledge.

We want to help you understand what you need, and why you need it.

We don’t want you to order equipment that you won’t need or use. Or if you have to make a decision between equipment or features, we want you to feel empowered to make the right decision for your brewery.

How we do it:

Our team of project leads has over 20 years of experience in designing bespoke breweries. From small to big to mom and pop or Big Beer, we have run the gamut of scenarios and currently have equipment in 16 countries and counting.

Our project leads also have experience with their respective local markets and can help you navigate any local nuances.

2. Layout Design

What we do:

Once we have your quote locked in, we will review your proposed layout to see what we feel can fit.

Your layout can be dimensions written on a napkin or a full-blown CAD drawing package from your design team. We’ve worked with it all.

Our team will provide you with PDF and DWG versions of our layout design that you may share with your team. We will also provide high-level MEP drawings for your local team to base their installation plans on.

If you would like to receive 3D drawings of your layout, so you can envision your brewery coming to life, we can provide that at an additional cost.

Why we do it:

We know the importance of a good layout design.

It is critical to know if your equipment will fit in your space — including unloading, hoisting, and load calculations (equipment is heavy!).

We also want to ensure that your equipment placement is in line with the installation of your different utilities, to avoid having AC ducting, electrical trays, etc. in the way.

How we do it:

Our team of in-house CAD designers can either take your hand drawings into the CAD world or work with your current drawings to fit models of our standard equipment.

3. Equipment Design

What we do:

Every single piece of equipment in your order gets its own detailed 2D drawing with important specifications called out.

We will set up a server link for your project that you and your team will have read-only access to. Our CAD team will save the most recent drawings here and then share them with the production team once approved. All drawings are available as PDF and DWG versions.

If you would like to receive 3D drawings of your equipment, we can provide that at an additional cost.

Why we do it:

This is where our name truly comes into play.

As we tailor the equipment to your brewery, we want to make sure that our designs meet your requirements.

You can also share these drawings with your local team so that they may plan their installation and utilities accordingly.

How we do it:

Your project lead will work with you to establish your requirements and share them with our CAD team.

4. Manufacturing

What we do:

We produce our commercial brewing equipment to the absolute highest standard.

We have found the best manufacturers to work with in China that hold up to the Bespoke standard.

As soon as your drawings are approved, we will send them to our production team and we’ll also give you a ready date!

Below are our typical manufacturing lead times:

- 75 days for a full system

- 45 days for tanks

Why we do it:

We know the quality of equipment can really make a huge difference to your product — and the overall success of your brewery.

Many of our competitors also produce here in China and we believe that locally made equipment can compete with some of the best in the world for the craft industry.

How we do it:

Our local team is based in Zhuhai, China and regularly visits suppliers for quality checks. With China being inaccessible to most of the world right now, having a team on the ground is critical.

We have the ability to conduct real-time inspections via video calls on the factory floor and even review designs to make sure everything is on point.

5. Shipping

What we do:

Our team will help guide you through the shipping process and what to expect. We work off of Ex-Works Ningbo for most of our shipments and can either work with your preferred freight forwarder or recommend one of ours.

Our CAD designers will put together container loading plans and we will arrange for a shipping quote from our preferred freight forwarder. These are all accessible via your project folders on the server.

Why we do it:

We believe it is essential to be aware of the shipping charges from the factory to your door, especially now, as global shipping costs are at historic highs.

Having a container loading plan to check and make sure everything will fit as planned will save time and money in the long run.

How we do it:

Based on your quote and our standard drawing, we can give you a ballpark number to set that expectation early in the process.

Then once all drawings have been approved, our CAD team will design the arrangement of equipment in the shipping containers and work to get you a more accurate quote.

Experience the Bespoke Way

If you’ve never started a brewery before, we’re here to help. If you’re an experienced brewer, we speak your language.

Contact us today if you think you’d like to work with us! Or if you just want more information about our services.

We always love a chat!