Here at Bespoke Brewing Solutions, we like to be helpful.

We are always chatting to people in the industry, trying to learn about the problems they are facing and the issues being discussed.

We try to write articles that can help with these issues – and give you ideas about how you can do things.

So today, we want to talk about grist – and the process by which it is made, in the early stages of the brewing process.

The mills are made in different sizes and contain rollers. And here’s the important part – the distance between these rollers is directly related to how fine the grist becomes – and this determines the efficiency and speed of the process of extracting wort (malt sugars) from the raw materials.

Pretty important stuff!

So, we decided to sit down with Mitch Bradey, a Sales Manager for Bintani – who are world renowned for their quality ingredients for brewing, beverages and food manufacturing.

We wanted to pick his brain, to understand the nuances of the crush and how it can impact efficiencies, flavors, and clarity.

The grist mill – how many rollers should you have?

This is a good question – and it depends on the beer you are brewing.

A two roller mill is your most basic type – and the cheapest price point as there is a stronger chance for smaller grains to slip through uncracked. You also have less control, as it’s more difficult to find the balance between fine grits and whole grains.

With a four roller grist mill, there are two points at which to control the crush parameters. Mitch says this allows greater consistency and more control over the crush.

‘The first roller is set a bit wider, while the second is a bit finer, so you can pick up all the smaller grains, allowing tighter control over the composition of the particle size.’

The grist acts as a natural filter for the wort to strain through. Different sizes are needed to ensure you get good lautering of the grist to extract sugars. The more sugar you can extract the better – as this means less malt is needed to reach your intended ABV therefore increasing your efficiency.

Basically – improved extract yield = more litres of beer!

How do you determine the optimum distance between the rollers?

Mitch says you are looking to find the largest possible gap without allowing whole grains through.

‘Really, the ultimate measure is to assess the resulting particle size rather than the mill gap. The perfect level of grind can only be found through experience – and likely a few slow lauters.’

In some breweries, the optimal gap may actually allow some whole grains through – with the end result being less headaches and actual ease of runoff in the brewery.

How can you test the gap length?

This is where it can get a bit tricky.

‘A feeler gauge or high precision calipers will get you in the ballpark. However, the resulting particle size is far more important than a number,’ says Mitch.

‘The feeler gauge will just give you a starting point – then the grist sieve will help the brewer dial it into perfection.’

How can you test grist coarseness? A Grist Sieve?

Mitch says the best way is to use a series of pans with specific screen sizes to assess the amount of large and small grits all the way to fine flour.

Grist Sieves come in different sizes to suit your needs, with the standard sizes being 1.4mm, 0.6mm, 0.25mm. You would also need a pan to go under the stack of sieves and a cap to cover them.

You are looking for a workable tradeoff between the fineness of the crush and lauterability.

What about pre-milled grist? Is that a thing?

Mitch says there are pros and cons to using pre-milled grist.

‘You do see pre milled grist in other countries and for the smaller brewpubs it reduces the dust and mess, while saving on both space and capital outlay,’ says Mitch.

‘But ultimately, with pre-milled grist you are at the mercy of the vendor’s mill gap setting which may not suit your particular brewing system. If you have your own mill, you can set the mill gap the best suits your application. It may have some appeal in Australia – If interested let us know.’

Savings found in getting the crush right

There are many savings to be found in ensuring a good crush.

‘There is also the obvious cash saving – but I think the real value lies in the improved lautering, with time saved for frustrated brewers who can avoid stuck mashes and refloating the mash bed.’

‘There’s also the quality factor, from improved runoff with less solids ending up in the kettle – resulting in a less astringent lower polyphenol runoff.’

Bintani Pro Tip: Signature Malt

Bintani’s Signature Malt is designed especially for the craft beer market.

Mitch says it’s the traceability that makes it special – it’s a single origin malt, that can be traced back to the exact paddock it came from.

‘We find the best performing barley each season, the area that has the best growing conditions for that year. And because the grain comes from the one area each year, it’s consistently the best quality.’

‘It’s about grain size and colour and yield and extraction potential – and it all needs to come together in the perfect combination to be worthy of the label.’

Want to know more?

If you’re wanting more information about the ingredients you need for the perfect grist, get in touch with Bintani.

We guarantee they will look after you – you just can’t find better quality ingredients.

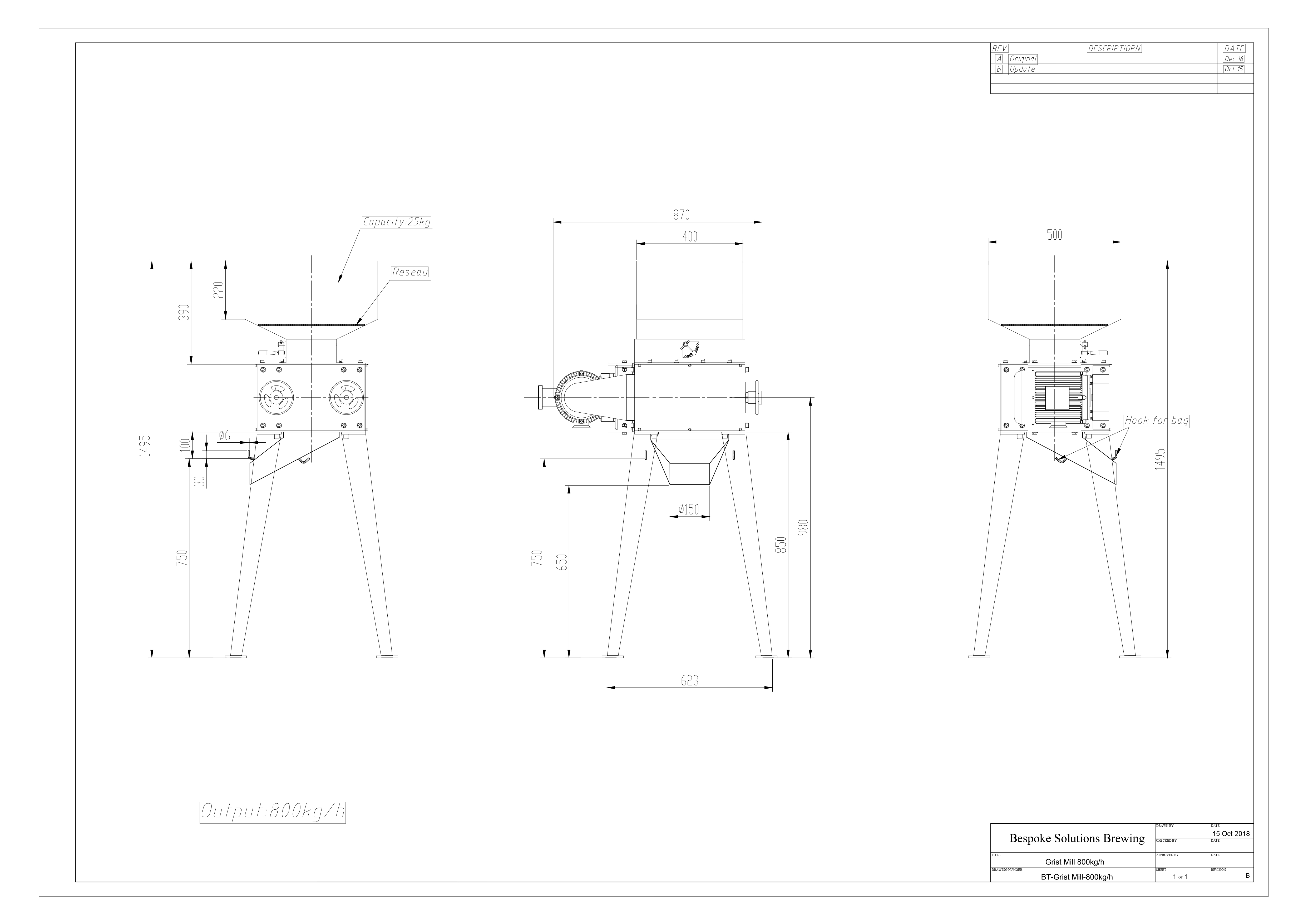

If you want to chat about the milling process and whether to purchase a grist mill, get in touch with our Bespoke Brewing Solutions team.