Believe it or not – designing a brewery layout is a fine art that takes real skill and experience.

It’s a delicate dance, between fitting as much as you possibly can into the space, while optimising for a smooth brewing process.

Getting the brewery layout right at the beginning of the project is the key to success.

So how can you ensure it is perfect?

Good news – you don’t have to! That’s our job.

Getting Started on Your Brewery Layout

In these early stages of planning your brewery, we will ask you three very important questions.

The answers will guide us on our recommendations for a brewing system that meets your needs.

- The size of your location – how much space do we have to play with?

- Your production goals and breakdown of different products – what are your goals?

- Your budget – how much do we have to work with?

Our flowmaster, Justin Fox put together a pretty nifty Brewery Scope Calculator to help extrapolate the needed brewhouse and cellar vessel sizings. This will ultimately determine the cost and necessary space for the equipment and supporting utilities.

Deciding Your Heating Method

Having an understanding of the utilities that are coming into the brewery is crucial as it will determine the heating options you will be able to consider.

We have had clients who have their hearts set on a steam-heated brewhouse and HLT but do not have a gas line into the building for a gas-fired steam boiler and there is not enough power for an electrical steam boiler. Upgrades to utilities can be a very drawn-out and expensive process!

We work to place equipment in relation to the utility to keep process piping or cabling to a minimum. Running utilities around a brewery can be another long and expensive process.

Working the Brewery Equipment into the space

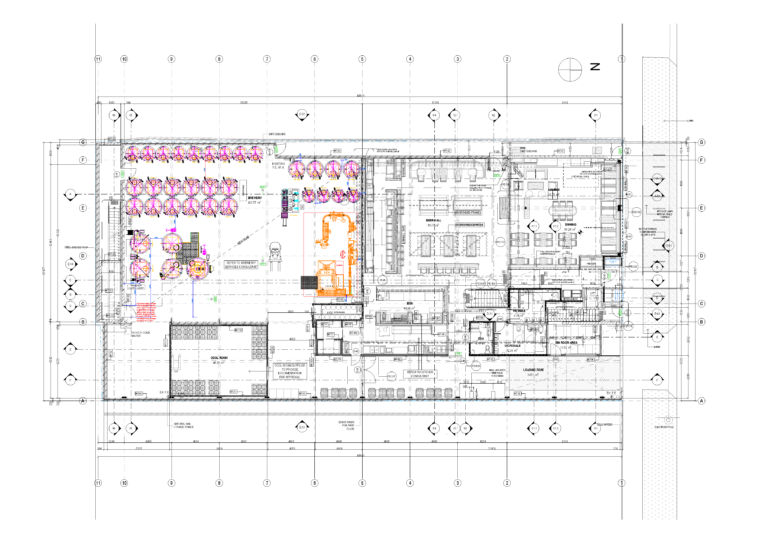

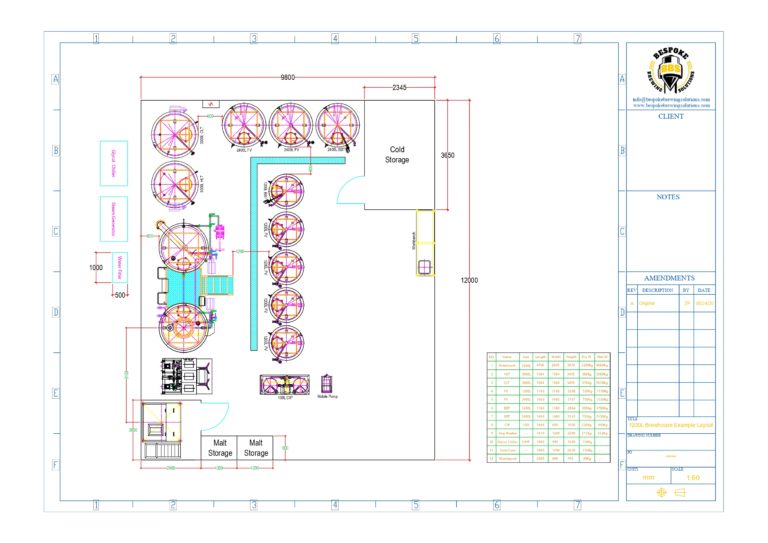

With all this information under our belts, we are moving into the serious part – a giant game of Tetris. Who doesn’t love a good Tetris session?

Our first goal is to get a 2D CAD drawing of the space from either the designer/architect or landlord. This drawing is critical – if we are working off an inaccurate

drawing, it can lead to huge and costly complications. As plans change we also ask for updates to be sent to us so we can copy our equipment into the latest and greatest layout to avoid any surprises.

Why Accuracy is Important

Underestimating weight can lead to foundation cracking. We also need to factor in trench drainage, which can take away the structural integrity of the slab if there’s too

much weight, and decrease height clearances if they need to be added to the slab.

Equipment dimensions and location need to be spot on. There is a reason our CAD drawings go to the millimeter and that is because if they are off we could have a serious problem on our hands.

If it gets to unloading day and a piece of equipment doesn’t fit into the space – the entire design is thrown off, and can lead to a domino effect of issues!

Also, underestimating weight can lead to foundation cracking and even structural failure if calculations are not done using wet weights. Having weight on or near trench drains can be annoying and lead to structural problems.

Get the Pencils Out!

Once we’ve worked out what equipment we need and how much we can fit into the space, we start drawing.

We create a series of diagrams that directly represent your brewery layout – exactly as it will appear in real life. As the project progresses, we will live and die by these drawings.

We provide a web link to clients which provides read-only access to your project files so you are on the exact same page we are.

Utilities – in our brewery layout design, we take things like piping routing and power outlets into consideration. Now that we are working in the 3D world too, we are able to provide a majority of the brewhouse process piping before shipping.

When we design your brewery layout, we have some important things in mind:

- The process path – we design a layout that flows with the brewing process, to avoid redundant tasks and movements. Movements take time – and time is money!

- Utilities – in our brewery layout design, we take things like piping routing and power outlets into consideration.

- Room for expansion – by planning for additional space ahead of time, you will save costs of having to redesign the equipment layout down the track. You can

also plan on utility routing and include the initial build-out. - General logic – think we’re stating the obvious? You’d be surprised at some of the blunders we have seen over the years! We ask the important questions, like what would be the best location for the glycol inlets and outlets for an FV or BBT? We ensure there is space to get your pallet through, your brite tank is near the cold room and the lauder tun is close to the door so you can easily bring malt out and kegs in. Sometimes it’s the simple things that have a lasting effect.

We Are Here to Help!

We know how important it is for everyone to be on the same page. Between us, your brewer, designer/architect, structural engineer, and contractor – there are a lot of chefs in the kitchen.

We understand this and are experts at managing these relationships – just ask our clients!

When you work with Bespoke Brewing Solutions, you have access to a consulting service, along with the highest quality equipment.

After doing this for as long as we have, in 17 different countries, we know what to look for. We know how things should flow and the best practice for your brewery layout.

We can preemptively identify where the roadblocks might pop up, so we can solve the issue before it arises.

If you’d like to hear directly from our brewing experts, you can check out this presentation we did for the Craft Beer Professionals 2023 Fall Virtual Conference.

If you’d like to work with us on your project, get in touch.