At Bespoke Brewing Solutions, we focus on helping breweries make their products better, faster, and more cost effective.

We have noticed many breweries don’t have the option to test new raw materials and ingredients – or experiment with recipe ideas on a smaller scale.

This means there is a risk that the flavor profile, bitterness and aroma is not what they expected and they have a large batch, which needs to be sold – and of course consumed!

Smaller fermenting lines give brewers the opportunity to take a portion of wort and experiment to their hearts’ desire! That way they can lock in a great recipe and scale to their bigger kit.

Here are some of the reasons we recommend installing a pilot batch brewing system.

Pilot Batch Brewing - Appealing to the Crafties

The beautiful aspect of craft beer (or any craft industry, for that matter) is the passion that goes into the art.

This passion by brewers has led to a plethora of different beer styles – with new ones coming out all the time.

The possibilities are endless! Changes in materials, temperatures and timing. can make subtle or extreme changes to the final product – whether for the good or bad. This passion typically transcends past brewers and through to the consumers, who are the wing beneath the sails of the craft movement.

Catering to their palette or even going beyond their current taste and introducing them to something new and exciting will set you apart from other brands. It will also ensure the freshness of this movement is continued for generations to come.

Market Research

A pilot batch brewing system enhances a brewers ability to:

- make small batch runs for clients to taste

- help consumers provide feedback

- possibly determine whether a certain brew might become a seasonal staple or even part of the core range

This process is a great way to keep people engaged and help them feel like they’re part of the process. Also – it’s just great fun!

Heart of Darkness Brewery in Saigon, Vietnam brew their Limited Release series in either 60L or 120L batch sizes. They have announced this on their website and social channels, creating quite the buzz among the craft beer community.

Another example is Fork and Brewer’s Little Forker series in Wellington, New Zealand. They even have a searchable archive to keep track of the beers they have released!

Meanwhile Urban Alley Brewery in Melbourne, Australia have a great set up that allows them to collaborate with gypsy brewers and experiment with exciting new beer stylers. Their system is one of the reasons they have been able to develop such an extensive range.

If you get a chance to visit these breweries you won’t be disappointed.

Yeast Brink or Propagator

Yeast can be a large expense for a craft brewery. It is therefore critical that while handling and fermenting – we are keeping it happy.

No one likes “upset” yeast as this anger can produce a number of different negative consequences to the end product.

We believe most yeast companies and their respective yeasts can be used over multiple generations – each manufacturer gives guidance on best practice.

Most yeast can also be propagated from a smaller pitch size, to your required pitch size. While this takes time, it can end up bringing your costs down.

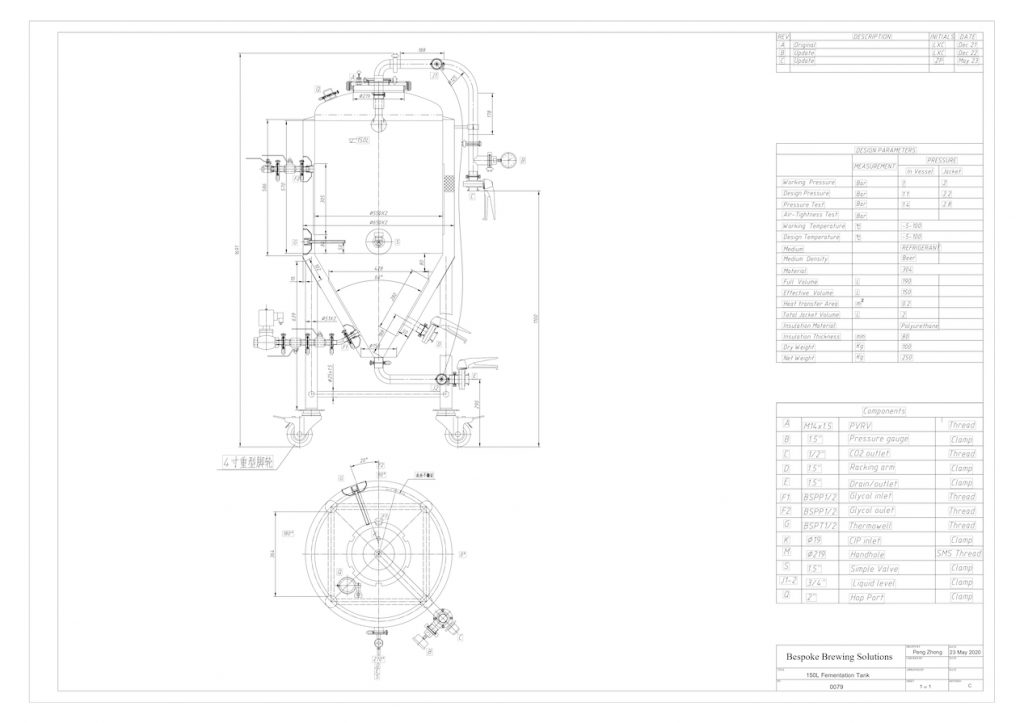

Also, with smaller jacketed FVs, you can connect them to your glycol system and even make them mobile (more on that in our next blog!)

This gives you the opportunity to wheel the FVs around the brewery and collect yeast to be used at a later time or push your slurry into the FV.

Pilot Batch Brewing - Get amongst it!

If you’re looking to get creative and want to experiment to find your perfect styles, let us know.

We can talk you through how the system works – and even provide you with a demonstration, if circumstances permit!

We know some great brewers who have embraced smaller fermenting lines to really expand their horizons. It’s an exciting prospect!

Get in touch if you’re ready to take it to the next level!